On September 2, 2021, the Association of Shipbuilders of Ukraine «Ukrsudprom» within the General Meeting of the Association held a Round Table on «Strategy for the development of the shipbuilding industry of Ukraine until 2030 — the first step in the revival of the maritime industry.»

The Association of Shipbuilders of Ukraine «Ukrsudprom» analyzed the activities of 13 largest enterprises (list attached) for 2019-2020.

In 2020, the total sales of shipbuilding enterprises amounted at UAH 3.5 billion, which is 18% less than in 2019

(UAH 4.3 billion), including shipbuilding — UAH 1.97 billion (91% by 2019), ship repair — UAH 1.0 billion (97.8%). Products worth UAH 0.5 billion (104%) were sold for export.

The number of employees in shipbuilding and ship repair decreased from 3950 people. in 2019 to 3470 people. in 2020, ie there was a loss of 480 jobs. The average maximum wage decreased by 3% and amounted to UAH 25,130. The share of shipbuilding and ship repair is constantly increasing in the structure of production and there is a significant decrease in other works (see Table 1).

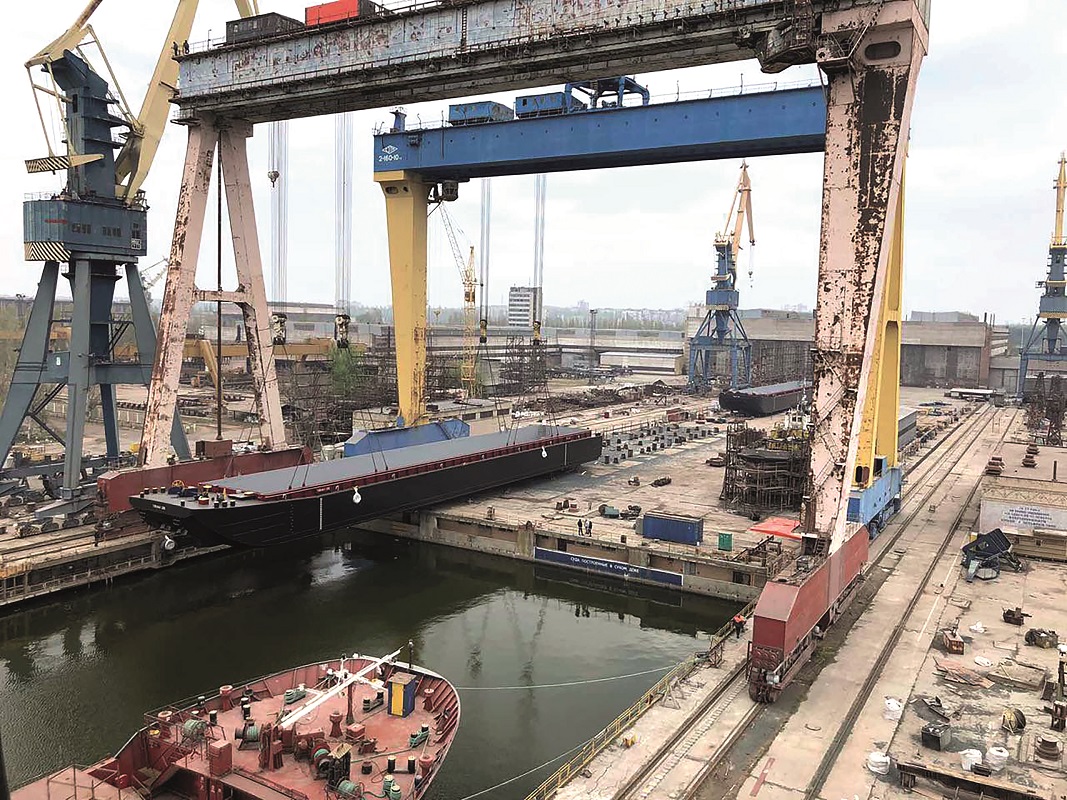

In 2020, 16 vessels, one ship and one craft were built at Ukrainian shipyards — a 57-meter berth created by the Palada plant. Two chemical tanker hulls built at Smart Maritime Group (SMG) shipyards for VEKA Shipbuilding WT B.V. and two barges built at the Okean plant for the Dutch company Eurobulk were sent for export.

The Ukrainian Navy received one reconnaissance ship of the Laguna project and the above-mentioned berth. The remaining vessels for their own needs were built at the shipyard of JV «Nibulon». These are 3 tugs and 5 barges. One SLG type barge at the Kiliya Shipbuilding and Shiprepair Plant for the Ukrainian Danube Shipping Company. At the Izmail shipyards «Dunaysudnoremont» and «Dunaysudnoservis», 3 barges were built to order of the holding company «AgroVista». The results of the work of shipyards «Ukrsudprom» are given in Table 2.

Shipbuilding takes place only at 6-7 shipyards, almost half of them on Nibulon for personal use. Only Okean and Smart Maritime Group work for export. The Kuznya na Rybalskomu plant has been fulfilling only military orders in recent years. Other companies are engaged in ship repair and metalworking.

Analyzing the results of work for the last 3 years, we can note that:

1. Since 2018, shipbuilding has been constantly increasing. In 2020, not only the number of built ships increased, but also their total gross tonnage — 17,807 tons against 16,180 tons in 2019. While in Europe, according to UNCTD, construction volumes decreased in 2020 by 30% (1,668,709 tons against 2,326,154 tons). Thus, our share in European shipbuilding increased from 0.7% to 1.1%.

2. In 2020, 18 ships were built, which is the best figure since 2013.

3. After a seven-year downtime, NW «Okean» resumed the work in 2019, in 2020 the plant began construction of non-self-propelled vessels.

4. In 2019, a 140-meter self-propelled transshipment vessel was built at the NIBULON GCC, which is the largest vessel built in the last 20 years.

5. Ship repair companies «Danube Ship Service» and «Danube Ship Repair» in 2019 began to build non-self-propelled vessels. So in 2020, they built a barge with a length of 128 m, which is the largest since independence.

6. In 2020, 34 new vessels with a total deadweight of 195.6 thousand tons were built and put into operation according to the projects of the Marine Engineering Bureau (in 2019, 24 and 181, respectively). The main vessels of the project RSD59, RST12C, RSD32M and the project PV300 were included in the best vessels of 2018 and 2020 (Significant Ships) of the British Royal Society of Naval Engineers.

7. The level of metal consumption in the industry can be largely judged by its condition. According to MMC «Center» in different years, the dynamics of deliveries of metal products «Metinvest» to Ukrainian shipbuilders was as follows: 2018 — more than 20 thousand tons; 2019 — more than 15 thousand tons; 2020 — 10.5 thousand tons.

8. For the first time, there is a reduction in jobs in shipbuilding and ship repair, which are associated not only with the COVID epidemic, but also the reduction of orders for 2021.

9. Positive changes in shipbuilding over the years have occurred mainly due to the construction of JV «NIBULON» own river fleet, foreign customers, orders of the Ministry of Defense of Ukraine and the agricultural holding company «AgroVista» and the shipping company «Grain-Transshipment».

At the meeting of the Ukrsudprom Association on the development of a strategy for state support of national shipbuilding on the initiative of the Office of the President and the Cabinet of Ministers of Ukraine Serhiy V. Gursky, General Director of Okean Shipyard, , commented on the establishment of credit agencies and reinvestment conditions in production:

«Currently, there is an order on the Ukrainian shipbuilding market on the foreign market. In 2020, the Okean plant built 2 dry cargo barges for the shipping company Eurobulk (Netherlands). After that, we processed new applications. Of the latter: the Dutch company invited us to build 5 ships in 2 years, the amount of funding reached about $ 30 million. Instead, the entire European market operates under a financial lending scheme. That is, they put money in their bank and after placing an order, guarantee their return. In 2019, Ukraine created an export credit agency in Ukraine, where there is no mechanism for attracting credit funds in shipbuilding — there is no state support.»

Also Elena Zhukova, the director of PKB MDEM, the Nikolaev enterprises representative, joined the discussion: «More attention at the state level needs to be paid to digital transformation of the shipbuilding enterprises. Design and construction of vessels is manufacture with long cycles and one of the most difficult in mechanical engineering. data information and resources involved in construction production.

In order to increase competitiveness and reduce the production cycle, as in the rest of the world, more digital technologies need to be introduced, and this is unfortunately not as simple as buying equipment, installing and operating it. Implementation of information systems is a more complex process, because it requires not only the purchase of software with its own specifics, not only the development of adaptation of work processes of enterprises, staff training to work with it. This means that there are all the elements of investment, consulting for the implementation of these projects. And without state support, it is very difficult to implement such initiatives. It is even very difficult to make the right decision.

The Maritime Cluster of Ukraine, in cooperation with the Ministry of Strategic Industries of Ukraine, is working on possible sources of funding, both state and donor.

It should also be noted that choosing a software and platforms that will not fail, will not be discarded, but will lead to their best use and the company will be able to gain an advantage is a great challenge. In general, it is very difficult to get advice on this issue not only in Ukraine, but in more developed countries — good consulting on this topic is a rare resource, in the shipbuilding industry in particular.

Therefore, one of the important projects of the Maritime Cluster of Ukraine together with the Ministry of Strategic Industries of Ukraine is the creation of a center of maritime competencies. Because companies need managers, IT specialists, not only the level of administration, but managers with strategic thinking, that is, who could operate with the adoption of a particular strategy. It is impossible to implement such comprehensive education or filling gaps quickly and cheaply, except through business, public organizations, and specialized ministries. »

Our shipbuilding companies and design organizations have sufficient potential to build different types of ships and warships, but the lack of government support and state orders in the domestic market can lead to the destruction of shipbuilding.